The industrial robotics market is witnessing a significant transformation. This positive outlook is supported by an anticipated growth of USD 55.1 billion in 2025, surging to an impressive USD 291.1 billion by 2035 at a CAGR of approximately 18.1%.

Increasing automation, advances in artificial intelligence (AI), and the rise of Industry 4.0 are redefining this landscape. And it is reflected in the adoption of advanced robotics in production lines and supply chains, increasing efficiency, productivity, and safety; while ensuring consistent quality and lowering operational costs for businesses.

Robotics has transformed warehousing, inventory management, and delivery systems.

Global supply chains are the backbone of modern economies, ensuring goods reach our homes, businesses, and stores. With growing demand and labour shortages, the logistics industry is turning to cutting-edge technologies to stay ahead. Automated guided vehicles (AGVs), robotic arms, and autonomous drones are performing tasks such as picking, packing, and sorting with speed and precision that far surpass human capabilities.

Think about robotic process automation, or RPA, also handling inventory management and order processing. It’s faster, more accurate, and frees up the team to focus on more strategic decisions.

Robotic breakthroughs powered by AI

Imagine a world where factories run 24×7, machines fix themselves, and production is faster than ever before. This isn’t science fiction; it is happening right now with factory floors buzzing with machines that can talk to each other, sharing real-time data about performance and efficiency, and completely transforming the way we build everything around us.

It does not stop there. AI is also optimizing the entire production line. It can analyse the workforce, identify bottlenecks, and suggest improvements that can drastically cut waste and speed up production.

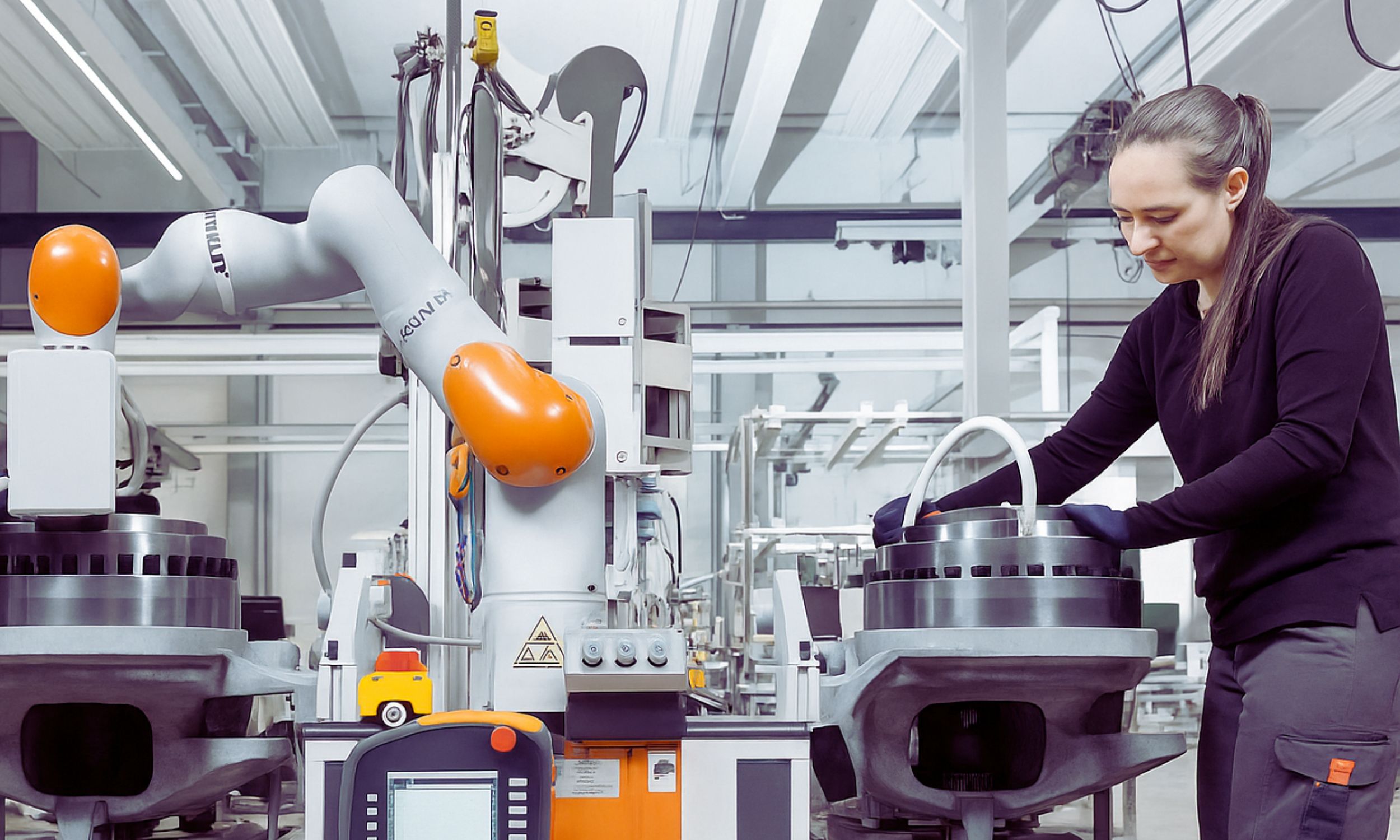

Another factor contributing to this transformation is the emergence of collaborative robots (cobots)—robots specifically designed with sensors and AI to safely operate alongside humans in shared work environments. These robots excel in performing precise, repetitive tasks while also enhancing workplace safety.

In addition, artificial intelligence (AI) and machine learning (ML) are transforming industrial robotics by facilitating AI-driven decision-making and predictive maintenance, which reduces downtime and prolongs the lifespan of robotic systems. Another key market driver is the increasing demand for adaptable and customizable robotic solutions. As the manufacturing landscape changes, companies are looking for robots that can be easily reprogrammed and tailored for various processes. This flexibility enables manufacturers to swiftly adjust to changing production requirements, thereby boosting competitiveness and operational efficiency.

Cobots tackle jobs that are dangerous or nearly impossible for humans—heavy-duty welding in high-temperature environments or handling toxic chemicals. They can perform these tasks with precision and consistency, reducing risks to human workers.

Apart from this, AI-powered robots learn from their environment and adjust to changing tasks on the fly. This significantly reduces errors, optimizes resource usage, and enables scalability in production, making them a cornerstone of smart factory operations.

Innovations transforming industries

When you combine the decision-making power of AI with the physical capabilities of robots, you get a nearly autonomous system. Picture a manufacturing line where AI algorithms oversee operations and interpret real-time data from every robot and machine. When a robot identifies a malfunction or requires recalibration, the AI directs it on the subsequent steps. These systems are also capable of adjusting to unforeseen circumstances, such as an unexpected surge in demand or a disruption within the supply chain.

For inventory management, agentic AI systems use real-time data and demand forecasts to optimize stock levels, ensuring raw material availability while preventing overstock. Autonomy minimizes carrying costs and enhances supply chain efficiency, allowing producers to keep lean stocks while meeting production schedules effortlessly.

This level of flexibility was unthinkable just a few years ago, but today, it is becoming the standard for cutting-edge factories.

To truly grasp the impact of AI and robotics on manufacturing, let’s look at some real-world examples.

In the automotive industry, companies like BMW are leading the charge. Their factories are equipped with robots that can assemble cars faster and more accurately than human workers, while AI systems oversee the entire process, optimizing workflow and ensuring quality.

Similarly, Tesla has integrated AI into its electric vehicle assembly lines, enabling faster and more efficient production of cars.

In the aerospace industry, AI-powered robots are assembling complex structures like aircraft wings with pinpoint accuracy.

Companies like Amazon have revolutionized warehouse operations with fleets of autonomous robots that navigate massive fulfilment centers, lifting and transporting heavy loads with ease. By taking over these tasks, robots are not just increasing productivity; they are making workplaces safer for everyone involved.

In the electronics sector, Samsung has adapted AI-driven automation to produce smartphones at an incredible scale, maintaining consistency and reducing defects.

It is not just big players that are making waves. Start-ups are also innovating, developing robots that can automate small-batch production or even custom manufacturing, making advanced technology accessible to smaller businesses.

Resilient & Sustainable Supply Chain

Supply chains involve numerous complexities and consist of suppliers, warehouses, manufacturers, and retailers collaborating for method optimization.

Robots kept things running during the COVID pandemic, helping the supply chains to bounce back. A critical factor that will continue to shape the global supply chains in 2025 is the relationship between the United States and China. Escalation of trade tensions amid the ongoing tariff war between the two economic superpowers could lead to potential decoupling of supply chains.

The restrictions in one geosphere could lead to opportunities for countries like India, Vietnam, Mexico, and Poland, which may emerge as alternative manufacturing hubs, supported by a dramatic transformation in logistics and supply chains through the integration of artificial intelligence (AI) and smart robotics.

Today, robotics and automation are streamlining many facets of supply chain operations.

Robots and automated warehouse technology are already helping businesses to make the most of their distribution hubs. The autonomous robots are also helping companies define the future supply chain by lowering long-term costs, providing labour and utilization stability, increasing worker productivity, lowering error rates, reducing the frequency of inventory checks, optimizing picking, sorting, and storing times, and increasing access to difficult or dangerous locations.

At the forefront of this transformation are autonomous vehicles and robots. Autonomous vehicles are revolutionizing the transportation of goods. From driverless trucks navigating cross-country routes to delivery drones dropping packages at your doorsteps, these technologies promise efficiency and precision.

The self-driving trucks equipped with advanced sensors, AI algorithms, and real-time connectivity reduce human error, lower fuel consumption, and minimize downtime. These trucks can operate 24/7 without the need for rest breaks, significantly cutting delivery time.

Inside warehouses, robots are taking over repetitive and labour-intensive tasks. From sorting items to picking and packing orders, these machines work tirelessly to meet consumers’ demands. By automating these processes, the companies have not only increased productivity but also reduced errors and improved workplace safety.

The benefits: faster operation, reduced costs, and a more sustainable supply chain.

Experts predict that by 2030, autonomous vehicles and robots will dominate supply chain operations, creating a seamless, tech-driven ecosystem. The integration of AI, IoT, and machine learning will further enhance these systems, making the supply chain more resilient, adaptive, and efficient.

Adapting to the shift

The question is not whether we should embrace these technologies but rather how audaciously and wisely we can execute that adoption. The challenges include substantial initial investments, as well as concerns regarding data privacy and potential job loss. And industries need to navigate these obstacles carefully. While automation is crucial, it is equally essential to retrain the workforce and address ethical issues to ensure a smooth transition.

While some traditional roles may phase out, new opportunities are emerging in areas like robot maintenance, AI system management, and advanced manufacturing technologies. The demand for skilled personnel capable of operating, programming, and maintaining these advanced systems is growing. Government, companies, and educational institutions are stepping up by creating programs to assist workers to reskill and adapt to these shifts. For instance, Germany, recognized for its robust manufacturing sector, has introduced vocational training programs designed to educate workers on how to work alongside collaborative robots and utilize AI tools effectively.