The evolution of collaborative robots (Cobots), with a dash of AI (artificial intelligence), in all likelihood, will transform industry.

In the history of industrial progress, few technologies have evolved as rapidly as robotics. From the massive robotic arms of the 1980s that welded cars behind steel barriers to today’s nimble, sensor-rich machines working in tandem with humans, automation has entered a new, collaborative era.

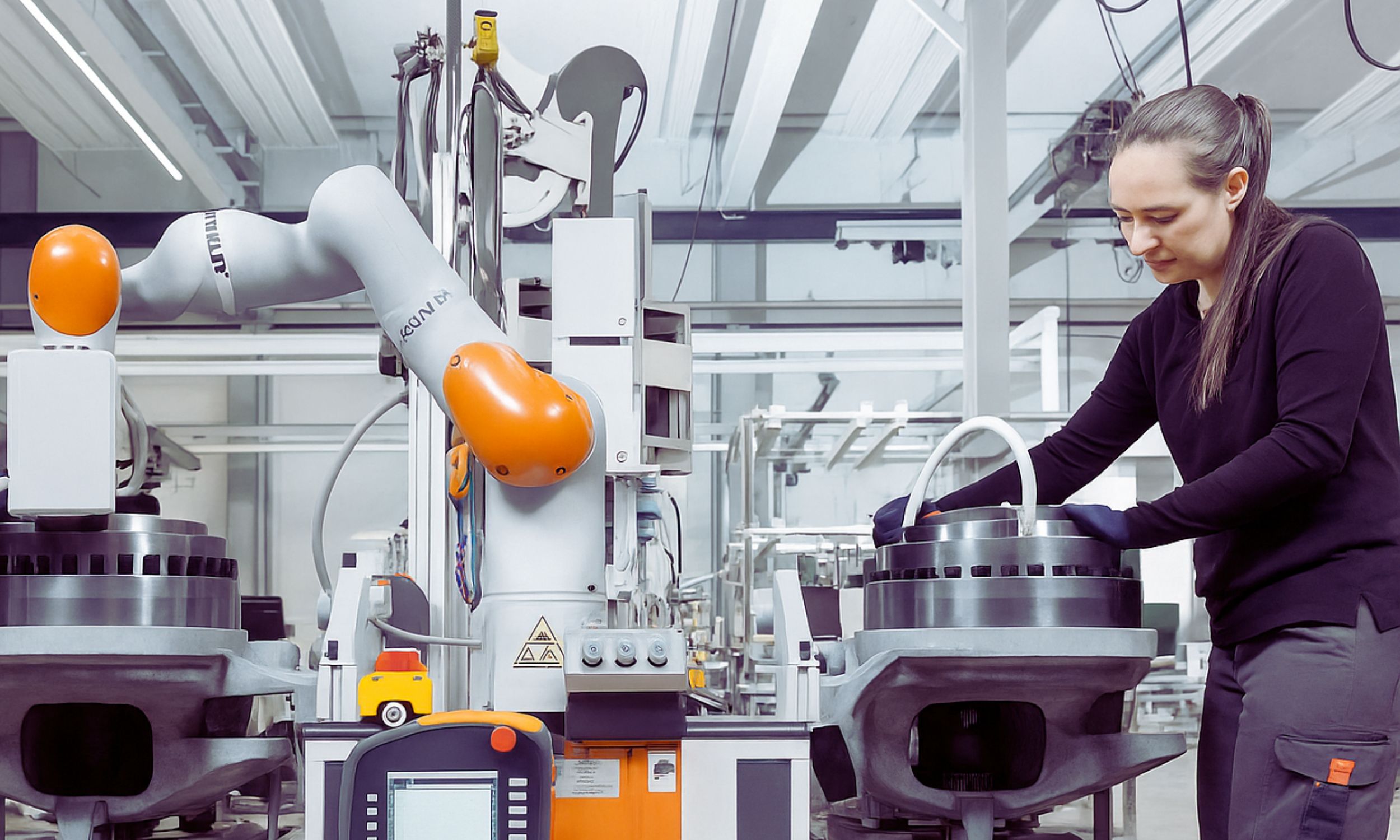

These next-generation robots—aptly named collaborative robots, or cobots—are transforming not just how work is done, but how it is experienced. Designed to work safely alongside people, cobots blend human judgment and creativity with robotic precision and endurance.

Unlike traditional industrial robots that require isolation for safety, cobots use advanced sensors, vision systems, and AI algorithms to detect human presence and adapt in real time. The shift from separation to collaboration marks a fundamental change in how industries approach productivity, design, and workforce development.

According to MarketsandMarkets, the global cobot market, valued at USD 2.7 billion in 2023, is projected to surpass USD 15 billion by 2030, growing at more than 27 percent annually. The drivers are clear: industries worldwide seek flexibility, safety, and efficiency amid shortages of skilled labours, demands for customisation, and digital transformation.

Why Cobots, Why Now?

The cobot revolution is not just about smarter robots—it’s about rethinking the future of work. Three converging forces have made them indispensable across sectors: the labour crunch, the need for flexibility, and the democratisation of automation.

a). The Labour Crunch

Advanced economies face acute worker shortages in manufacturing, logistics, and healthcare. Cobots fill critical gaps by handling repetitive, ergonomically challenging, or precision-driven tasks—without fatigue or error.

India faces a similar but distinct challenge: a skill imbalance rather than a worker’s shortage. Manufacturing contributes nearly 17 percent to India’s GDP, but demand for trained technicians far exceeds supply. In Pune and Chennai, Tata Motors and Hyundai reportedly use cobots for welding and painting operations, reducing error rates and protecting workers from heat and fumes.

In sectors like electronics, where micro-level accuracy is vital, cobots are helping India climb the value chain—from assembly to advanced component manufacturing.

b). The Need for Flexibility

Traditional robots are expensive to install and reprogramme, and are suited mainly for large, repetitive production runs. Cobots, in contrast, are lightweight, mobile, and easily reprogrammable, perfect for short-run production or seasonal surges.

This flexibility makes them ideal for India’s 63 million small and medium enterprises (SMEs), which often lack the capital or floor space for traditional automation. In Coimbatore and Rajkot, cobots are now used in foundries and precision-engineering workshops for polishing and inspection—tasks once deemed too delicate for full automation.

c). The Democratization of Automation

Falling sensor costs, open-source robotics software, and plug-and-play design are lowering barriers to entry worldwide. In India, home-grown startups like Systemantics, Asimov Robotics, and GreyOrange are designing affordable cobots tailored to local conditions—robust enough for dusty factory floors, yet precise enough for electronics and pharma.

From Factory Floors to Hospital Corridors

Cobots are no longer confined to manufacturing—they have found homes in laboratories, warehouses, hospitals, farms, and even classrooms. Their cross-sector versatility is reshaping entire economies.

i). Manufacturing: Precision Meets Productivity

The birthplace of the cobot revolution remains the manufacturing floor. Global leaders like Universal Robots’ UR10 and FANUC’s CRX-10iA now work beside technicians at BMW, Ford, and Siemens, improving throughput and reducing defects.

In India, this transformation is equally visible. Mahindra & Mahindra’s Igatpuri plant uses cobots for precision engine assembly, cutting error rates by 20 percent. Panasonic’s Noida facility relies on AI-enabled cobots for soldering and inspection, while Tata Electronics employs them for packaging and quality assurance.

Compact, easily reconfigurable cobots enable mass customisation—a game-changer for India’s fast-moving electronics and auto-component sectors.

ii). Pharmaceuticals: Automation with a Sterile Touch

In the global pharmaceutical industry, precision and sterility are paramount. Cobots are automating contamination-sensitive processes such as vial filling, pipetting, and packaging under clean-room conditions.

During the COVID-19 pandemic, cobots became essential in vaccine production lines, performing tasks too repetitive or risky for humans under strict bio-containment.

India’s USD 50 billion pharmaceutical industry, one of the world’s largest, has embraced this shift. Dr. Reddy’s Laboratories and Sun Pharma deploy cobots for GMP-compliant packaging and labelling. AI-powered analytics enable real-time correction, flagging anomalies before they lead to costly recalls—making “automation with a sterile touch” a new industry standard.

iii). Healthcare: Precision, Safety, and Scalability

Perhaps the most transformative application of cobots lies in healthcare. Surgical robots such as the da Vinci System and CMR Surgical’s Versius have revolutionised minimally invasive procedures—offering sub-millimetre precision and faster recovery times.

India has rapidly adopted this frontier. More than 100 hospitals now use robotic systems, and the country’s first indigenous surgical robot, SSI Mantra (developed in Bengaluru), has slashed procedure costs by half. Beyond the operating theatre, cobots are finding work in hospital corridors. AIIMS Delhi and Apollo Hospitals are piloting robots that deliver medicines, disinfect rooms using UV light, and transport supplies—boosting hygiene and freeing up nursing staff for patient care.

The global healthcare robotics market is projected to hit USD 35 billion by 2032, and India’s share is set to expand sharply as AI and 5G improve clinical precision.

iv). Logistics and Warehousing: The Agile Workforce

E-commerce has redefined customer expectations—speed and accuracy are non-negotiable. Cobots, equipped with AI navigation and machine vision, are the unsung heroes of this revolution.

At Amazon, Ocado, and DHL, cobots assist with picking and palletising. In India, Flipkart and Reliance Retail use similar systems in massive fulfilment centres in Haryana and Karnataka.

GreyOrange, a Gurugram-based pioneer, exports its “Butler” cobots to over 70 countries, exemplifying India’s global contribution to warehouse automation.

AI-driven cobots can now predict workflow bottlenecks, redistribute tasks, and reduce idle time by up to 60 percent, helping India’s logistics sector—poised to reach USD 380 billion by 2025—operate smarter and greener.

v). Agriculture and Food Processing: Gentle Automation

Agriculture, long resistant to automation, is being reshaped by cobots equipped with computer vision and tactile sensors. They can harvest delicate crops, sort produce, and package food hygienically.

In India, agritech startups like AgNext and Samhitha Crop Care use cobots for quality grading and precision spraying, while Amul and ITC Foods explore robotic arms for cold-chain packaging and portioning. These technologies address twin challenges—labour scarcity in rural areas and the need for consistency in exports—helping farmers climb the value chain.

When AI Meets Robotics: Intelligence at the Edge

AI allows cobots to interpret visual data, recognise objects, and plan movements autonomously. A welding cobot can identify defects, adjust its trajectory, or coordinate seamlessly with another unit—all without human intervention.

In India, the Wipro PARI robotics division in Pune is pioneering AI-driven cobots that use machine-learning models to detect anomalies and self-correct in milliseconds—crucial for automotive and electronics manufacturing.

Safety First: Redefining Trust Between Human and Machine

Cobots are built on a safety-by-design philosophy. Traditional industrial robots move at dangerous speed and force, requiring cages for protection. Cobots, instead, use force-limiting sensors, vision systems, and real-time motion planning to keep humans safe. Indian firms deploying cobots—like Bajaj Auto and Hero MotoCorp—report improved worker morale, fewer injuries, and higher efficiency.

The Economic Dividend: Smarter, Leaner, More Inclusive

Cobots are more than technological marvels—they are economic multipliers. According to McKinsey, companies adopting cobots achieve productivity gains of 20–40 percent and ROI within 18 months.

In India, a 2024 Deloitte-CII study estimates that automation could raise manufacturing productivity by up to 40 percent, adding USD 300 billion to GDP by 2030.

Enabling MSMEs and Regional Growth

Cobots could democratise Industry 4.0 across India’s Tier-2 and Tier-3 cities—Surat, Ludhiana, Coimbatore, Aurangabad—where clusters of MSMEs struggle with quality control and labour turnover. Affordable cobots bridge this gap, enabling precision production without massive capital outlay.

Policy and Incentives

Government schemes such as SAMARTH Udyog Bharat 4.0, Production Linked Incentives (PLI) for electronics and pharmaceuticals, and Digital India are fostering automation ecosystems.

States like Tamil Nadu and Karnataka are setting up robotics parks and skill centres, while NITI Aayog’s AI Mission supports research in intelligent automation. Together, they form the backbone of India’s transition to “smart manufacturing.”

Sustainability and Net-Zero Synergy

Cobots also contribute to sustainability goals. By optimising material use, reducing energy waste, and enabling precision assembly, they shrink industrial carbon footprints—aligning with India’s Net-Zero 2070 commitments.

In sectors from automotive to textiles, “green robotics” is becoming the bridge between competitiveness and climate responsibility.

The Human Element: Coexistence, Not Replacement

Automation often triggers fears of job loss. Yet cobots offer a more balanced narrative—they handle the 3D tasks: dull, dirty, and dangerous—freeing humans for creative, analytical, and supervisory roles.

At SMC Corporation Japan, cobots transfer hazardous materials while humans focus on quality. In India, Bajaj Auto and Tata Motors echo this model, with cobots managing high-temperature assembly and humans performing precision checks.

New roles are emerging—robot supervisors, AI trainers, cobot maintenance engineers—demanding a digitally fluent workforce.

India’s education system is catching up fast. IIT Madras, IIT Delhi, and the National Skill Development Corporation (NSDC) now offer specialised programs on cobot programming and human–robot interaction.

The result: a new social contract between human intellect and robotic precision—coexistence over competition.

Challenges on the Road Ahead

Despite their promise, cobots must overcome key challenges before achieving full-scale integration:

- Integration Complexity: Retrofitting cobots into legacy systems demands calibration, connectivity, and cybersecurity safeguards.

- Standardisation Gaps: Global safety norms exist, but interoperability across brands remains uneven.

- Data Privacy and Ethics: AI-enabled cobots collect vast operational data—securing and anonymising it is critical, especially in healthcare or defence.

- Cultural Resistance: Fear of automation persists among workers and unions. Transparent communication and upskilling are essential.

- Cost Barriers: For smaller Indian firms, even low-cost cobots can strain capital budgets without easy access to industrial credit.

Addressing these barriers requires a collaborative strategy—uniting manufacturers, policymakers, educators, and financiers. The National Mission on Advanced Manufacturing, now being revived, could play a catalytic role in mainstreaming cobot adoption across sectors.

The Future: Cobots from Boston to Bengaluru

As AI, 5G, and edge computing mature, the line between human and machine collaboration will blur even further.

Imagine a factory where cobots sense worker fatigue and slow their pace, or hospitals where robots interpret tone to assess urgency. Such systems are already in development—in Boston labs and Bengaluru startups alike.

India is emerging as both a major user and exporter of collaborative robotics. Bengaluru’s innovation hubs, Pune’s automation firms, and Hyderabad’s electronics clusters are designing affordable cobots for global markets.

Future Indian cobots will be multilingual, cloud-connected, and energy-efficient—crafted for the realities of small workshops as much as smart factories. The same technology empowering Germany’s carmakers or Japan’s hospitals could soon drive precision engineering in Coimbatore or patient logistics in Kolkata.

Cobots, in this sense, are the mobile phones of industrial transformation—a leapfrogging technology empowering millions, not just mega corporations.

Conclusion: Toward a New Industrial Renaissance

The rise of cobots marks more than a technological milestone—it signals a cultural shift in how humanity views work, technology, and partnership. In this new paradigm, humans and machines no longer stand on opposite sides of the factory floor; they co-create value in shared spaces.

For India, this is an opportunity to craft a distinctly inclusive model of automation—one that empowers workers, strengthens MSMEs, and advances sustainability. The synergy between human creativity and robotic precision will define competitiveness in the decades to come.

In the end, the story of cobots is not about robots becoming more like humans—it’s about humans becoming more capable through robots. Together, they form the blueprint of a new industrial renaissance—smarter, safer, and unmistakably collaborative.